Do you aspire to craft your own unique blend of aquavit, capturing the essence of this cherished Scandinavian spirit?

You’ll learn everything there is to know about distillation from the fundamentals to how to perfect your technique, and we’ll go over all of the steps in this comprehensive guide.

Discover the secrets of the perfect Aquavit distilled with passion, as we travel to discover the journey of flavor exploration and craftsmanship.

Understanding the Distillation Process

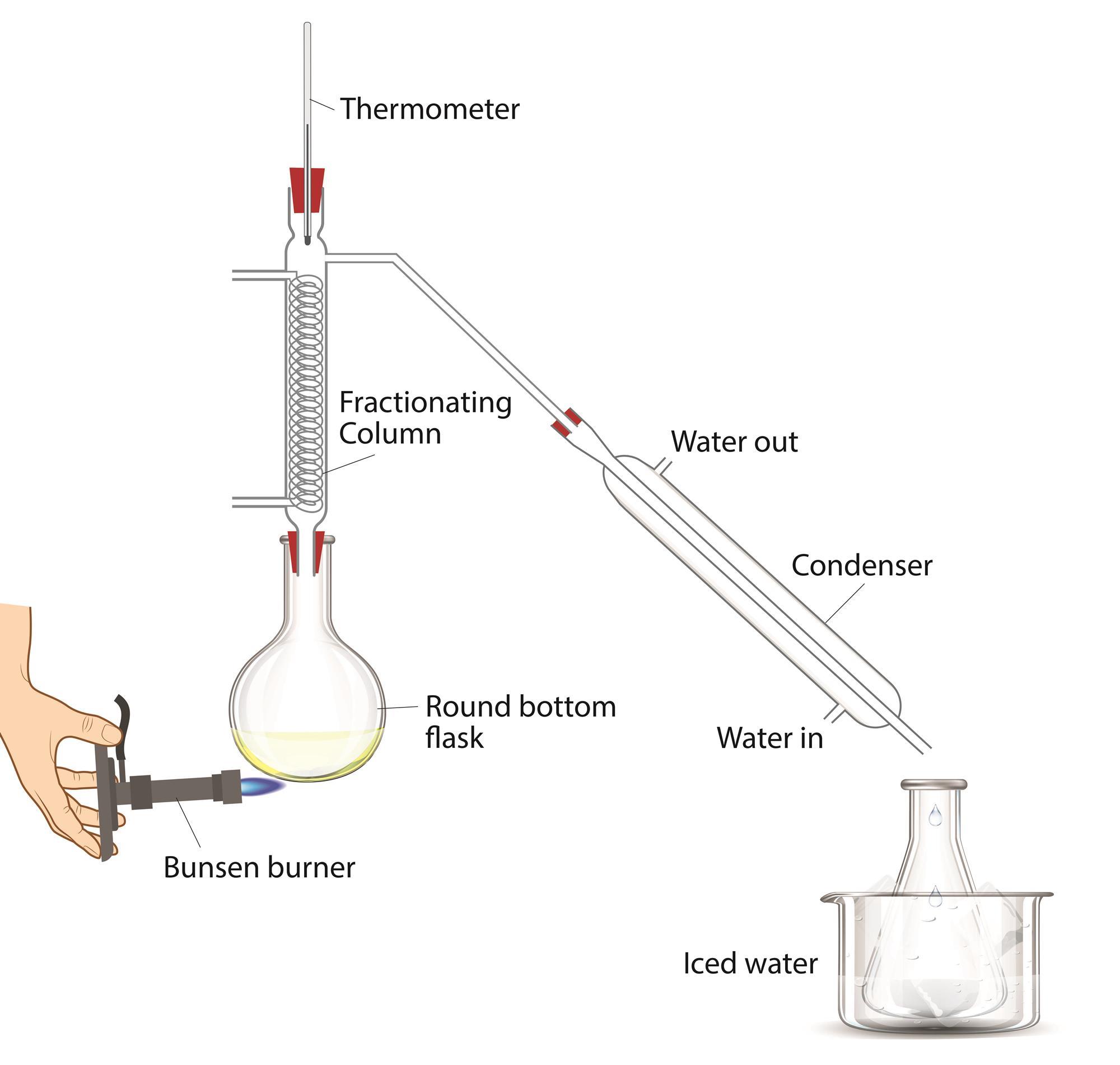

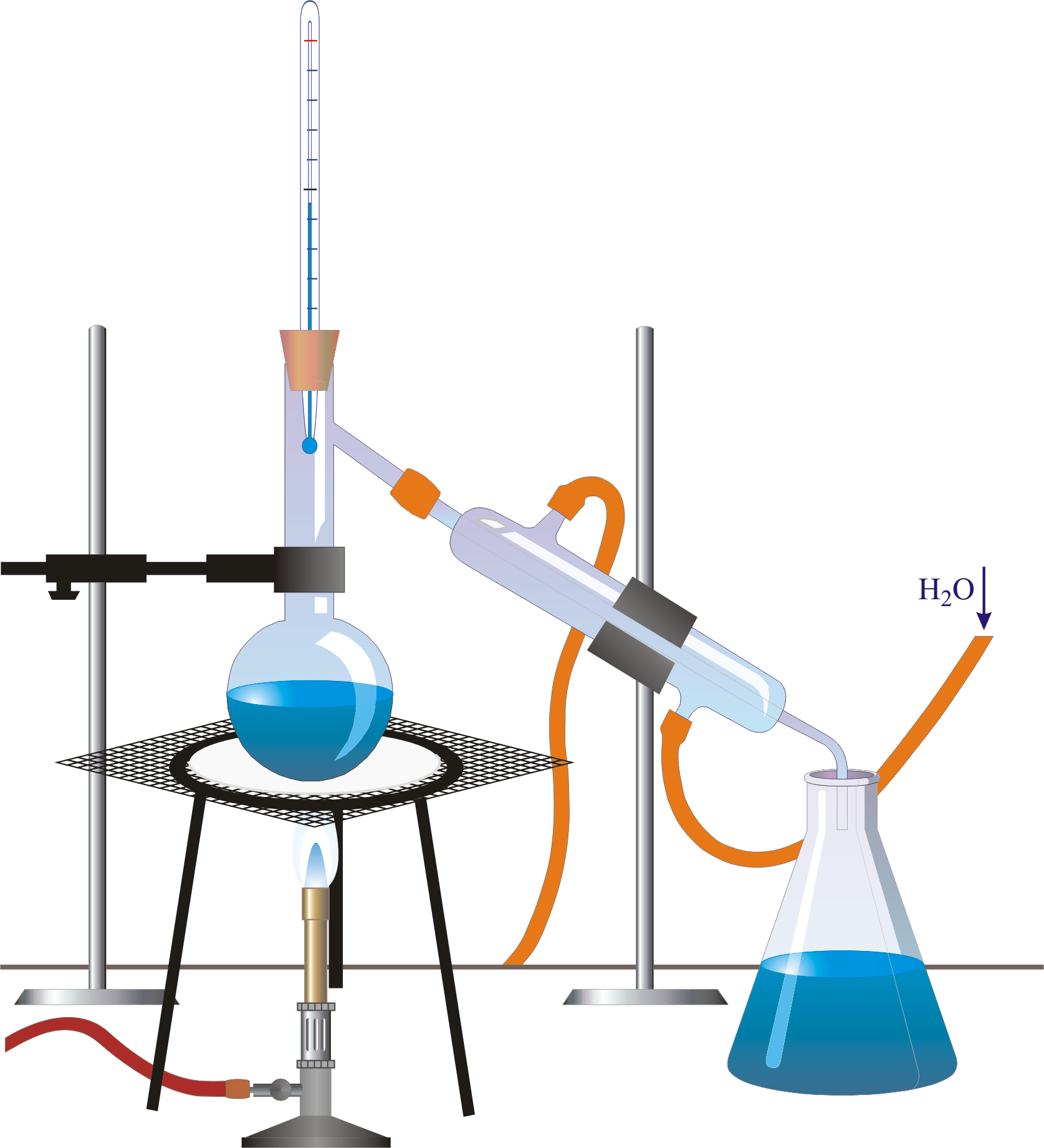

Understanding the distillation process is paramount for aspiring aquavit artisans seeking to master the craft of creating this cherished Scandinavian spirit. At its core, distillation is the transformative alchemy that converts a simple fermented mash into a refined and flavorful liquor. This intricate process involves carefully heating the fermented liquid to vaporize the alcohol, separating it from the water and other impurities, and then condensing it back into a liquid form. To embark on this journey, one must first grasp the basics of distillation – the fundamental principles that govern the conversion of liquid to vapor and back again. Armed with this knowledge, distillers can navigate the complexities of the process with confidence and finesse.

When venturing into the world of aquavit distillation, acquiring the appropriate equipment is essential. From the sturdy still to the precise thermometers and hydrometers, each piece plays a crucial role in ensuring a successful distillation run. Pot stills, with their traditional design and ability to retain flavors, are favored by many artisanal distillers for crafting high-quality aquavit with depth and character. Conversely, column stills offer efficiency and consistency, making them a popular choice for larger-scale production. Regardless of the equipment chosen, meticulous attention to detail and adherence to best practices are paramount for achieving optimal results.

Central to the art of distilling aquavit are the key ingredients that impart its distinctive flavor profile. Juniper berries, with their piney aroma and earthy undertones, are the backbone of traditional aquavit recipes, lending a quintessentially Nordic essence to the spirit. Complementing the juniper are an array of botanicals such as caraway, dill, coriander, and citrus peels, each contributing its own unique flavor nuances and complexities. Together, these ingredients undergo a transformative journey during distillation, as the heat and pressure coax out their essential oils and aromatic compounds, infusing the spirit with layers of flavor and depth.

In the pursuit of crafting exceptional aquavit, understanding the distillation process is not merely a technical endeavor but a journey of exploration and discovery. With each distillation run, distillers have the opportunity to refine their technique, experiment with different ingredients, and hone their craft. By embracing the art and science of distillation, aspiring aquavit artisans can unlock a world of endless possibilities, where creativity knows no bounds and the pursuit of perfection is a lifelong endeavor. So, whether you’re a seasoned distiller or a curious novice, embark on this journey with an open mind and a thirst for knowledge, and let the alchemy of distillation guide you towards crafting your own signature blend of aquavit.

Preparing for Distillation

When embarking on the journey of preparing for distillation, meticulous attention to detail and thoughtful planning are paramount to success. This pivotal phase sets the stage for the entire distillation process, laying the foundation for creating a superior-quality aquavit that delights the senses and captivates the palate. At the outset, the selection of the recipe serves as the blueprint for crafting a unique and flavorful spirit that reflects the distiller’s vision and expertise. Whether drawing inspiration from time-honored traditions or daring to innovate with bold new flavor combinations, the choice of recipe sets the tone for the distillation journey ahead. With a clear vision in mind, the next step is sourcing and preparing the finest ingredients, ensuring that each component contributes to the complexity and character of the final product. From hand-selecting juniper berries imbued with aromatic oils to meticulously measuring out botanicals with precision, every detail matters in the pursuit of excellence. With the ingredients assembled and prepared, attention turns to safety precautions, an indispensable aspect of the distillation process that cannot be overlooked. As the alchemical transformation unfolds within the confines of the still, distillers must remain vigilant, safeguarding against potential hazards and ensuring a safe and controlled environment. From fire hazards posed by heating elements to the risk of chemical exposure from volatile compounds, adherence to safety protocols is non-negotiable. By taking proactive measures to mitigate risks and prioritize safety, distillers can embark on the distillation journey with confidence, knowing that they are well-equipped to navigate the challenges that lie ahead. In the realm of aquavit distillation, preparation is not merely a prelude to the main event but an integral part of the journey itself, shaping the outcome and setting the stage for success. Armed with a carefully curated recipe, meticulously sourced ingredients, and a steadfast commitment to safety, distillers are poised to embark on a transformative odyssey of flavor exploration and craftsmanship. So, as you prepare to embark on your own distillation journey, remember to approach the process with intentionality, attention to detail, and a dedication to excellence. The path to mastering the art of distillation begins with meticulous preparation – are you ready to take the first step?

Distillation Techniques

When delving into the art of distillation, understanding the nuances of different techniques is essential for achieving optimal results and unlocking the full potential of the spirit being crafted. Two primary distillation methods, pot and column distillation, offer distinct advantages and are often chosen based on the desired outcome and scale of production.

Pot vs. Column Distillation

- Pot Distillation: Known for its traditional craftsmanship and ability to retain complex flavors, pot distillation involves heating the fermented liquid in a pot still, allowing the vapors to rise and be collected before condensing back into liquid form. This method is favored by artisanal distillers for its ability to produce small batches of spirits with depth and character.

- Column Distillation: In contrast, column distillation, also known as continuous distillation, employs a column still to achieve a more efficient and consistent production process. The fermented liquid is continuously fed into the column, where it undergoes multiple distillation stages, resulting in a purer and more neutral spirit ideal for large-scale production.

Temperature Control and Monitoring

Temperature control is a critical aspect of the distillation process, influencing the separation of alcohol from water and other impurities. Distillers carefully monitor and adjust the temperature throughout the distillation run to optimize the extraction of desirable compounds and minimize the presence of unwanted flavors. By maintaining precise control over temperature, distillers can achieve a fine balance between flavor retention and purification, ensuring a high-quality end product.

Fractional Distillation for Flavor Refinement

Fractional distillation is a specialized technique used to refine and enhance the flavor profile of spirits, including aquavit. During this process, the vaporized alcohol passes through a fractionating column, where it undergoes multiple condensation and evaporation cycles. This repeated exposure to varying temperatures allows for the separation of different components based on their boiling points, resulting in a more refined and nuanced spirit. Fractional distillation is particularly effective for aquavit, as it enables distillers to selectively capture and concentrate the aromatic compounds and essential oils from botanical ingredients, enhancing the depth and complexity of the final product.

The Distillation Process Step by Step

Navigating through the intricate steps of the distillation process requires a keen understanding of each stage’s significance in shaping the final product. The journey begins with mashing and fermentation, where grains or other raw materials are combined with water and enzymes to convert starches into fermentable sugars. This crucial step sets the foundation for the subsequent stages, imparting essential flavors and characteristics to the base mash. Once fermentation is complete, the next phase involves loading the still, a pivotal moment where the magic of distillation truly begins to unfold. Whether using a traditional pot still or a modern column still, the careful placement of the fermented mash sets the stage for the extraction of alcohol and flavor compounds.

Mashing and Fermentation

- Mashing: The process of combining grains or raw materials with water and enzymes to convert starches into fermentable sugars.

- Fermentation: The transformation of sugars into alcohol and carbon dioxide by yeast, resulting in the formation of alcohol-rich liquid known as “wash” or “beer.”

Loading the Still

- Pot Still: Traditionally crafted pot stills are loaded with fermented mash, allowing for the gentle heating and evaporation of alcohol and flavor compounds.

- Column Still: In contrast, column stills feature continuous loading mechanisms, enabling a more streamlined and efficient distillation process for larger-scale production.

Once the still is loaded, the distillation run commences, marked by the steady application of heat and the meticulous collection of distillate. As the temperature rises, alcohol vapors begin to rise through the still, where they encounter various components that influence their journey. The process of heating, collection, and cuts involves carefully monitoring temperature fluctuations and making precise adjustments to capture the desired fractions of distillate. Through a series of “cuts,” distillers separate the heads, hearts, and tails, each containing different concentrations of alcohol and flavor compounds. This meticulous process ensures that only the finest and most flavorful portions of the distillate are collected, resulting in a superior-quality spirit that captivates the senses and delights the palate.

Flavoring and Aging

In the realm of distilling aquavit, flavoring and aging are pivotal stages that contribute to the depth, complexity, and overall character of the final spirit. Traditionally, aquavit is flavored using a combination of botanicals, each carefully selected for its aromatic properties and flavor profile. Juniper berries, with their distinctive piney aroma, are a cornerstone ingredient in traditional aquavit recipes, imparting a quintessentially Nordic essence to the spirit. Complementing the juniper are an array of botanicals such as caraway, dill, coriander, and citrus peels, each contributing its own unique flavor nuances and complexities. These botanicals undergo a transformative journey during distillation, infusing the spirit with layers of flavor and depth.

Traditional Botanicals Used for Flavoring

- Juniper Berries: Known for their piney aroma and earthy undertones, juniper berries are the backbone of traditional aquavit recipes.

- Caraway: Adds a distinctive spicy and slightly sweet flavor to the spirit.

- Dill: Imparts a fresh and herbaceous quality, with hints of anise and citrus.

- Coriander: Contributes citrusy and floral notes, enhancing the overall complexity of the flavor profile.

- Citrus Peels: Provide bright and zesty accents, balancing the richness of other botanicals with their refreshing acidity.

In addition to traditional botanicals, distillers are increasingly exploring innovative ways to experiment with unique flavor profiles, pushing the boundaries of tradition and creativity. From infusing aquavit with exotic spices and herbs to incorporating unconventional ingredients like sea buckthorn or lingonberries, the possibilities for flavor experimentation are virtually limitless. This spirit of innovation and exploration has led to an exciting renaissance in the world of aquavit, with distillers and enthusiasts alike embracing the opportunity to create bold new expressions that challenge convention and captivate the senses.

Experimenting with Unique Flavor Profiles

- Exotic Spices and Herbs: Cinnamon, cardamom, star anise, and other spices add warmth and complexity to the flavor profile.

- Unconventional Ingredients: Sea buckthorn, lingonberries, and other Nordic botanicals offer unique and unexpected flavor experiences.

- Barrel Aging: Oak barrels impart rich vanilla, caramel, and spice notes, adding depth and complexity to the spirit over time.

When it comes to aging aquavit, distillers have a range of options and considerations to explore. While traditionally consumed young and unaged, aquavit can benefit from aging in oak barrels, where it undergoes a gradual maturation process that enhances its flavor and smoothness. The type of oak, size of the barrel, and duration of aging all play a role in shaping the final character of the spirit. Additionally, distillers may choose to experiment with alternative aging methods, such as infusing aquavit with oak staves or aging it in other types of barrels, to achieve unique flavor profiles and expressions.

Aging Options and Considerations

- Oak Barrel Aging: Imparts rich vanilla, caramel, and spice notes, enhancing the flavor and complexity of the spirit.

- Duration of Aging: Longer aging periods result in smoother, more mellow spirits with greater depth and complexity.

- Alternative Aging Methods: Experimentation with oak staves, different types of barrels, or innovative aging techniques offers endless possibilities for flavor development.

Quality Control and Testing

In the realm of distilling aquavit, quality control and testing are essential processes that ensure the consistency, integrity, and excellence of the final product. From evaluating alcohol content to conducting sensory analysis for flavor and aroma, each step in the quality control process plays a crucial role in maintaining the highest standards of craftsmanship and ensuring a spirit that delights the senses and captivates the palate.

Evaluating Alcohol Content

- Hydrometer Testing: Distillers use hydrometers to measure the alcohol content of the spirit, ensuring it meets regulatory requirements and desired specifications.

- Density Measurement: Density measurements provide additional insights into the alcohol content and overall purity of the spirit, helping to identify any deviations from the target values.

Sensory Analysis for Flavor and Aroma

- Organoleptic Evaluation: Distillers rely on sensory analysis techniques to assess the flavor, aroma, and overall quality of the spirit. This involves tasting and smelling the spirit to identify any off-flavors, impurities, or inconsistencies.

- Panel Testing: Panels of trained tasters may be convened to evaluate the spirit collectively, providing diverse perspectives and insights into its sensory attributes.

Adjustments and Fine-Tuning

- Blending: In cases where the spirit falls short of the desired flavor profile, distillers may opt to blend it with other batches or ingredients to achieve the desired balance and complexity.

- Maturation: For spirits undergoing aging, regular monitoring and sampling allow distillers to track the progress of maturation and make adjustments as needed to optimize flavor development.

As distillers navigate the quality control and testing process, meticulous attention to detail, adherence to best practices, and a commitment to excellence are paramount. By embracing a rigorous approach to quality assurance, distillers can uphold the integrity of their craft and produce aquavit that exceeds expectations and delights discerning palates. From the evaluation of alcohol content to the sensory analysis of flavor and aroma, each step in the quality control process serves as a testament to the dedication and passion of those who strive to create exceptional spirits that stand the test of time. So, as you savor each sip of aquavit, know that behind every bottle lies a commitment to quality, craftsmanship, and the pursuit of perfection.

Bottling and Presentation

As the culmination of a meticulous distillation process, bottling and presentation are pivotal steps that not only preserve the integrity of the aquavit but also enhance its allure and appeal to consumers. From filtering and clarifying to selecting the perfect bottle and label design, every aspect of the bottling process contributes to the overall perception and enjoyment of the spirit.

Filtering and Clarifying

- Filtration: Distillers may employ various filtration techniques, such as activated carbon or diatomaceous earth filtration, to remove impurities and achieve clarity in the spirit.

- Clarification: Through the careful monitoring of temperature and precipitation, distillers clarify the spirit to ensure a pristine appearance and optimal visual appeal.

Choosing the Right Bottle and Label Design

- Bottle Selection: The choice of bottle is not merely practical but also symbolic, reflecting the essence and identity of the aquavit. Whether opting for a classic flask-style bottle or a sleek modern design, distillers seek to convey a sense of craftsmanship and quality.

- Label Design: The label serves as the ambassador for the aquavit, conveying essential information about its origin, ingredients, and distillation process. Distillers often invest considerable time and effort into designing labels that are both visually striking and informative, capturing the attention of consumers and enticing them to explore further.

Tips for Storage and Serving

- Storage: To preserve the integrity of the aquavit, it is essential to store it in a cool, dark place away from direct sunlight and extreme temperatures. Proper storage conditions help maintain the spirit’s flavor and aroma over time, ensuring a consistently enjoyable drinking experience.

- Serving: When serving aquavit, consider the occasion and the preferences of your guests. Whether enjoyed neat, on the rocks, or as a component of cocktails, aquavit offers versatility and flexibility that cater to a wide range of tastes and preferences.

As consumers increasingly seek out premium spirits that offer both exceptional quality and aesthetic appeal, the importance of bottling and presentation cannot be overstated. By paying careful attention to every detail, from filtration and clarifying to bottle selection and label design, distillers can create a truly immersive and memorable experience for consumers. Whether displayed on the shelves of a liquor store or showcased in the home bar of a connoisseur, a well-bottled and impeccably presented aquavit is sure to leave a lasting impression and cement its status as a cherished favorite among spirits enthusiasts. So, as you raise a glass of aquavit to toast the joys of life, take a moment to appreciate the artistry and craftsmanship that went into bottling and presenting this beloved Scandinavian spirit. Cheers to the journey of discovery and delight that awaits with each sip!

Regulatory Compliance and Licensing

Navigating the intricate landscape of regulatory compliance and licensing is paramount for distillers venturing into the production and sale of aquavit. Understanding and adhering to legal requirements is not only essential for ensuring the legality of operations but also for upholding standards of quality and safety in the production process.

Legal Requirements for Producing and Selling Aquavit

- Alcohol Regulations: Distillers must comply with local, state, and federal regulations governing the production, distribution, and sale of alcoholic beverages. This includes obtaining appropriate licenses and permits, adhering to production standards, and paying applicable taxes.

- Labeling Requirements: Aquavit labels must accurately reflect the spirit’s ingredients, alcohol content, and origin, in compliance with labeling regulations. Misleading or inaccurate labeling can result in fines or legal repercussions.

Obtaining Necessary Permits and Licenses

- Distillery License: Distillers must obtain a distillery license from the appropriate regulatory authorities to legally produce aquavit. This process typically involves submitting an application, undergoing inspections, and meeting specific criteria regarding production facilities and practices.

- Sales Permit: In addition to a distillery license, distillers may need a separate permit to sell aquavit to consumers or wholesale distributors. This permit may vary depending on the intended sales channels, such as retail stores, bars, or restaurants.

Compliance with Labeling and Packaging Regulations

- Label Approval: Before bottling and distributing aquavit, distillers must ensure that their product labels comply with regulatory requirements. This may involve submitting label designs for approval to ensure accuracy and compliance with labeling regulations.

- Packaging Standards: Distillers must also adhere to packaging standards, such as bottle sizes, closures, and packaging materials, to ensure consumer safety and compliance with regulatory requirements.

As distillers navigate the regulatory landscape, they must remain vigilant and proactive in ensuring compliance with legal requirements at every stage of the production and distribution process. From obtaining necessary permits and licenses to adhering to labeling and packaging regulations, compliance is essential for maintaining the integrity and legality of their operations. By prioritizing regulatory compliance, distillers can build trust with consumers, mitigate legal risks, and position themselves for success in the competitive spirits market. So, as you savor the distinctive flavors of aquavit, rest assured that behind every bottle lies a commitment to quality, craftsmanship, and compliance with regulatory standards. Cheers to the journey of exploration and enjoyment that awaits with each sip!

Troubleshooting and Common Pitfalls

When it comes to distilling aquavit, navigating potential troubleshooting scenarios and common pitfalls is crucial for ensuring a smooth and successful production process. From addressing off-flavors to resolving equipment issues and navigating legal and regulatory challenges, distillers must be prepared to tackle various obstacles that may arise along the way.

Dealing with Off-Flavors

- Identification: Distillers must first identify the specific off-flavors present in the aquavit, which may result from factors such as improper fermentation, contamination, or poor-quality ingredients.

- Remediation: Once the off-flavors are identified, distillers can take appropriate remedial actions, such as adjusting fermentation conditions, filtering the spirit, or incorporating flavor-neutralizing agents to restore balance and purity.

Resolving Equipment Issues

- Regular Maintenance: Distillers should prioritize regular maintenance and inspection of distillation equipment to prevent issues such as leaks, clogs, or malfunctions that can compromise the quality of the aquavit.

- Technical Support: In the event of equipment issues, distillers can seek assistance from technical experts or equipment manufacturers to diagnose and resolve the problem promptly, minimizing downtime and production delays.

Addressing Legal and Regulatory Challenges

- Compliance Review: Distillers must conduct regular reviews of their operations to ensure compliance with evolving legal and regulatory requirements governing the production, labeling, and sale of aquavit.

- Consultation: Seeking guidance from legal experts or regulatory agencies can help distillers navigate complex legal frameworks, address compliance issues, and mitigate the risk of penalties or fines.

By proactively addressing troubleshooting scenarios and common pitfalls, distillers can minimize disruptions to production, uphold the quality and integrity of their aquavit, and maintain compliance with legal and regulatory standards. Through careful attention to detail, rigorous quality control measures, and a commitment to continuous improvement, distillers can overcome challenges and emerge stronger, more resilient, and better equipped to deliver exceptional spirits that delight and inspire consumers. So, as you embark on your journey in the world of aquavit distillation, remember to embrace challenges as opportunities for growth, innovation, and mastery of your craft. Cheers to a future filled with success, satisfaction, and the pursuit of perfection in every bottle of aquavit!

More related questions

- What is the history of aquavit?

Aquavit has roots tracing back to the 15th century in Scandinavia, particularly in Norway and Sweden. Originally crafted for medicinal purposes, it evolved into a beloved spirit infused with herbs and spices like caraway, dill, and fennel. Over time, aquavit became intertwined with cultural and celebratory traditions, such as weddings, holidays, and festive gatherings. Its name derives from the Latin term “aqua vitae,” meaning “water of life,” reflecting its significance in Scandinavian culture. Today, aquavit continues to be cherished for its unique flavor profile and serves as a symbol of heritage and craftsmanship in Nordic countries and beyond.

- How does the distillation process differ for aquavit compared to other spirits?

The distillation process for aquavit differs from other spirits primarily in its choice of botanicals and aging techniques. While traditional spirits like whiskey or vodka may focus on grains or potatoes, aquavit utilizes a distinctive blend of herbs and spices, such as caraway, dill, and fennel, to impart its signature flavor profile. Additionally, some aquavits undergo aging in oak barrels to enhance their complexity and smoothness, while others may be bottled shortly after distillation to preserve their fresh, vibrant character. This emphasis on botanical infusion and aging methods sets aquavit apart from other spirits and contributes to its unique taste and cultural significance in Scandinavian tradition.

- What safety precautions should be taken when distilling aquavit?

Safety is paramount when distilling aquavit. Distillers should ensure proper ventilation in their distillation area to prevent the buildup of potentially harmful fumes. Additionally, it’s crucial to monitor and control the temperature during the distillation process to prevent overheating or fires. Distillers should also handle flammable materials, such as alcohol and cleaning solvents, with care and store them in designated areas away from ignition sources. Proper training in the use of distillation equipment and adherence to safety protocols can help minimize the risk of accidents and ensure a safe and successful distillation process. Regular maintenance and inspection of equipment also play a vital role in preventing potential hazards and ensuring a safe working environment for all involved.

- What are the key botanicals used in aquavit?

The key botanicals used in aquavit vary depending on regional traditions and personal preferences of distillers. However, some common botanicals include caraway seeds, dill, fennel, anise, coriander, and citrus peel. These botanicals contribute to the distinctive flavor profile of aquavit, with caraway typically being the dominant flavor. Additionally, some variations of aquavit may include other herbs and spices, such as cumin, cardamom, or cinnamon, to add complexity and depth to the spirit. The specific combination and proportions of botanicals are often closely guarded secrets passed down through generations or unique to each distillery, resulting in a wide range of flavors and styles across different brands and regions.

- How does aging affect the flavor of aquavit?

Aging significantly influences the flavor of aquavit by allowing it to develop complexity, smoothness, and depth over time. During aging, the spirit interacts with the wood of the aging vessel, typically oak barrels, absorbing compounds like tannins, lignins, and vanillin. These interactions impart subtle flavors of caramel, vanilla, and spice, while also mellowing harsh notes and refining the spirit’s overall character. Additionally, prolonged aging allows for oxidation to occur, further enhancing the bouquet and softening the spirit’s mouthfeel. The duration of aging and the type of barrel used can vary, resulting in a wide range of flavor profiles, from light and delicate to rich and robust. Ultimately, aging plays a crucial role in shaping the nuanced flavors and aromas that distinguish aged aquavit from its younger counterparts.

- What are the legal requirements for producing aquavit?

To produce aquavit, distillers must adhere to legal requirements that vary depending on their country or region. These regulations typically govern aspects such as licensing, permits, and labeling. Distillers may need to obtain specific permits or licenses to operate a distillery and produce alcohol legally. Additionally, there may be regulations regarding the ingredients used, the distillation process, and the alcohol content of the final product. Labeling requirements often include accurate information about the product’s alcohol content, ingredients, and origin. It’s essential for producers to familiarize themselves with the legal requirements in their jurisdiction and ensure compliance to avoid penalties and maintain the integrity of their product.

Chef Carlos Meier has been working in the culinary industry for more than a decade at popular and known places. Carlos got his first job in a kitchen at a fast food restaurant washing dishes. He quickly moved up the ranks to bussing tables and wait-assisting.